Machining has always been about precision, speed, and reliability but in today’s highly competitive world of manufacturing, efficiency is everything. If you are producing parts for automotive or aerospace or high-tech products, the tools that you choose directly affect your bottomline. Indexable drills, high-speed drills, tungsten carbide-based end mills and threading inserts can make a big difference.

This isn’t simply an update on the older tools. The new tools provide the most efficient method of working, which decreases the amount of downtime, saves money and provides better results using less effort. Look over each of them and see how they aid manufacturers in drilling into deeper holes, efficiently cut and get the job done faster.

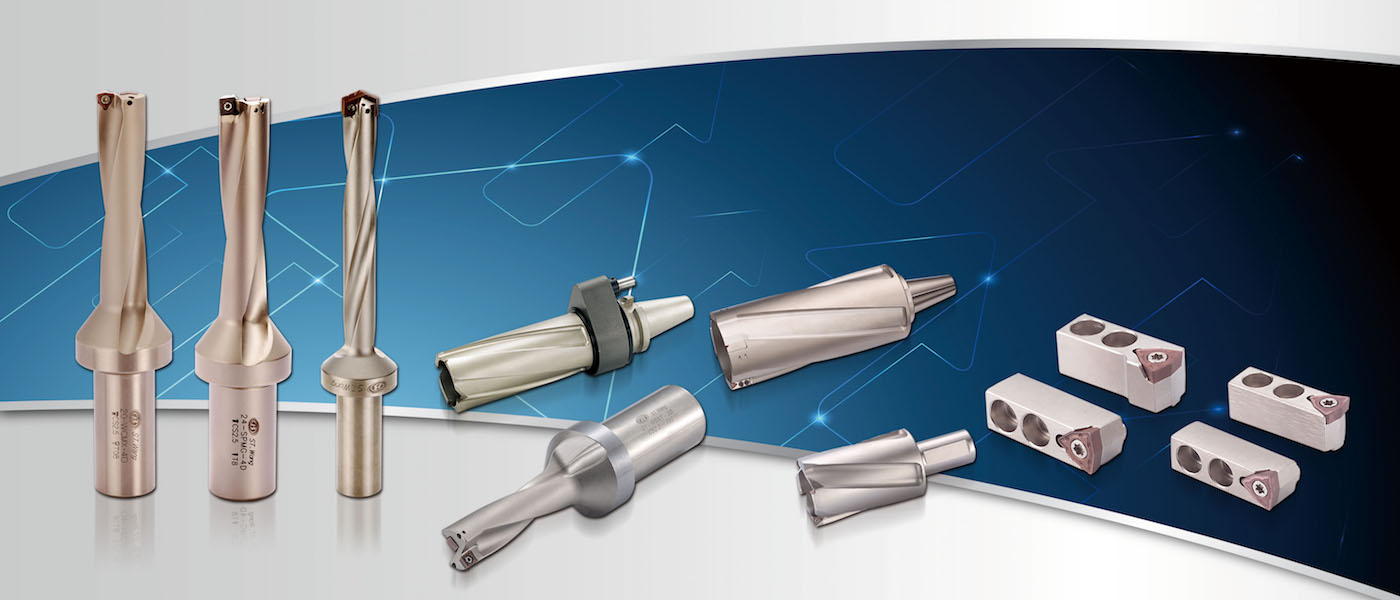

Image credit: stwang-tw.com

Indexable Drills: More Holes, Less Hassle

Up until recently, drilling big holes was expensive and took a lot of time. The drills were prone to wear out they needed sharpening and in some cases, they slowed production lines. This is why more machinists are moving to an indexable drill. Instead of having to replace the entire tool every time it becomes dull, you just change the cutting inserts and you’re back to work in a matter of minutes.

The effectiveness of indexable drills is what makes them stand out. They’re designed for long-running runs, heavy-duty performance, and easy maintenance. With the option of replacing inserts, you can reduce waste, lower inventory of tools and ensure that your equipment runs longer. SHANG TZANG WANG ENTERPRISE Co. Ltd. provides disposable drills that provide consistent performance when used in large diameter applications. This upgrade will reduce the time to repair for shops who perform repetitive hole machining.

High-Speed Drills for Modern Requirements

In a production environment where time is the most valuable commodity high-speed drills have been designed to be fast, without sacrificing accuracy. They work best with robust materials and quick cycles. From medical instruments that are precise to automotive parts that are high volume These drills are utilized everywhere.

Modern high-speed drills feature optimized flute designs with cutting edge coatings which reduce friction and resist the buildup of heat. They also increase the tool’s life. This means less tool changes as well as less breakage, which means increased production. If you’ve ever had to deal when a drill broke during your work, switching to high speed drills can be a real revelation.

Tungsten Carbide End Mills: Reliable Performance Cut After Cut

When it comes to milling carbid end mills made of tungsten are the most reliable tool for use in shops. They’re famous for their hardness as well as their heat resistance and ability to cut through hard materials without losing edge sharpness. These tools are reliable for every task, from roughing large sections to finishing corners.

What is what makes tungsten carbide-based end mills unique is their flexibility. They are able to be modified to meet various applications that range from aluminum to titanium with different flute counts and Helix angles. For machinists who need both precision and durability, carbide end mills provide the ideal balance between the removal of material as well as clean surface finishes.

Threading Inserts: Tiny Tools, Big Impact

Creating threads might seem like a small part of the process, but it’s actually one of the most important. A poor thread can ruin the quality of a product. That’s why a high-quality threading insert matters. The tiny, replaceable inserts are engineered to cut internal or external threads with extreme accuracy and reproducibility.

Unlike traditional taps and dies that wear unevenly threading inserts provide steady results across many cycles. If one edge becomes dull you can simply index to the next cutting edge there is no need to take off the tool or regrind. It’s simple, cost-effective, and tidy. Machine builders appreciate threading inserts, not only for their speed but also for their dependability. You can be certain that the threads you use are going to fit perfectly the first time. There are no second passes, no rework and no worry about rejecting parts.

Bottom Line

Modern machining is time-sensitive. You can’t waste it. The most efficient shops of today have switched to smarter tools and more flexible solutions for tooling. The cutting tools of today aren’t just better at accuracy, they also simplify workflows, cut down on shifts, improve life span and improve user-friendliness. The result? It means that less time is spent on troubleshooting so that more time is spent producing high-quality parts. In an industry with higher demands and smaller margins, manufacturers can remain competitive by using tools that work better.