Innovation is essential for electronic devices. Manufacturers are constantly seeking new ways to revolutionize the manufacturing process of their products as demand grows for smaller, flexible and high-performance electronics. Flex circuit production is one of the most cutting-edge techniques that has garnered lots of attention.

Flexible printed circuit boards, also known as Flex Circuits (PCBs) provide a host of advantages over rigid PCBs. These remarkably versatile circuits are made to bend or twist and conform to different shapes, making them perfect for applications that require complex designs, space constraints, or enhanced durability.

Flex circuits let manufacturers expand the boundaries of design by offering a an elastomeric base that can adjust to the shape and size of the product. This flexibility allows more creative and compact design, ultimately leading to lighter and smaller devices. Imagine a phone that forms around your hand, the wearable health tracker that is discreetly slid over your wrist, or even an appliance that has a seamless, ergonomic form. Engineers and designers can translate their designs into reality thanks to Flex Circuits, enabling users to explore a myriad of new possibilities for product design.

Beyond the aesthetic benefits, the durability of flex circuits makes them stand distinct from their rigid counterparts. Traditional PCBs can be damaged due to shock, vibration and repeatedly bending. Flexible circuits are built using specially designed materials that are able to withstand these dangers. They’re therefore highly robust even in the toughest conditions. This quality is vital in industries like aerospace and automotive, or medical, that require electronic components to withstand severe conditions.

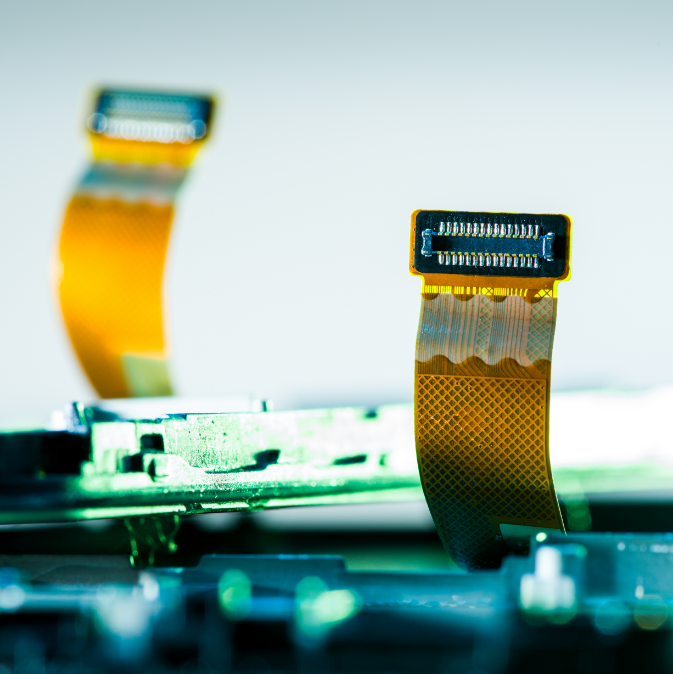

The manufacturing techniques employed in flex circuit production contribute significantly to their impressive capabilities. Flex circuits are constructed using a flexible substrate such as polyester or polyimide instead of rigid PCBs which consist of multiple layers fiberglass and copper. The substrate forms the foundation of the circuit and permits it to be bent or bent while still maintaining electrical connectivity. Flex circuit manufacturers are able to precisely cut circuit trace, create intricate interconnects, and connect components into the flexible substrate with the latest manufacturing techniques.

Surface mount technology (SMT) lets components be positioned directly on the flex circuit. This enhances flexibility and functionality. SMT allows manufacturers to mount electronic components on top of flex circuits. Bulky connectors are eliminated and the overall device size can be reduced. This method is not just efficient and conserves space, it also enhances signal integrity, reduces weight and improves thermal management.

The flex circuit manufacturing techniques also allow rapid prototyping and is scalable to meet the requirements of larger quantities. The versatility of circuit designs allows for rapid iterations during the prototyping process, speeding up the development of products. Due to their capacity to be produced in high volumes through automated manufacturing processes, flexible circuits are cost-effective to produce large quantities. Flex circuits are a great option for businesses looking to quickly bring innovative ideas into the marketplace.

It is crucial to be able to rely on a reliable source for flex circuits, as demand is expected to grow. It is essential to work with trusted, seasoned manufacturers in order to ensure the precision and consistency of the production of flex circuits. They have the experience and know-how to guide you through the design process, provide valuable insight into the selection of materials and guarantee compliance with industry standards.

At the end of the day, flex-circuits are indispensable components that allow modern electronic assemblies to attain the maximum level of complexity. Flex circuits are the heart of various complex systems, ranging including displays in consumer goods to military applications. Flexible substrates that are able to navigate through tiny spaces effortlessly, allow engineers to design complex designs and still fit into the dimensions of the assembly. While a variety of other forms of circuit routing exist, their mechanical and electrical properties simply can’t compare to those of the flex assembly solution when it comes to meeting tough size restrictions. Flexible circuits are the most suitable option when you need complex interconnections, combining multiple different technologies into a flawless design.